SAFETRACK BAAVHAMMAR AB

ELECTRICAL CABLE CONNECTION SYSTEMS

PinBrazing Railway

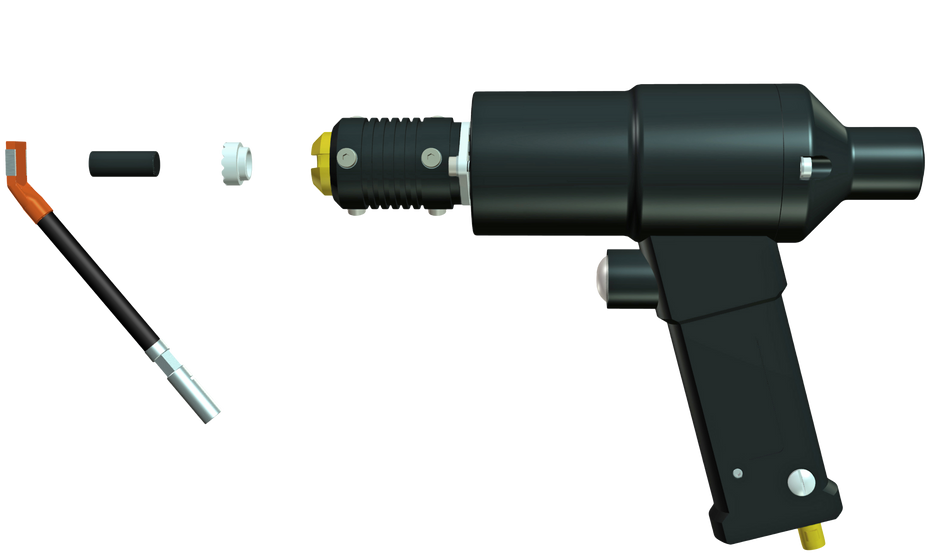

Safetrack® patented Pin Brazing system is a unique battery driven brazing method to applicate electrical connectors to steel structures like railway rails. Used for connecting signal bonds, rail bonds, power and return bonds and for grounding cables. The system is also used with great advantage within cathodic protection (CP) systems.

The secret of the patented system is that a special silver based alloy, developed for the purpose, is melted (650°C) by a totally controlled energy distribution from high power batteries thru the patented electronic and automated brazing device.

- Low temperature. The only melting part is a special silver alloy. Melts at 650°C (1200°F)

- Safe for the material. It is a Silver Brazing Method. Does not melt the work material down as welding methods does

- Works in any weather condition. Rain and snow is no more a problem

- Achieve Broken Rail detection, caused by the drilled hole for the joint bars, by attaching rail bonds on side of rail head

- Fast, the PinBrazing process only takes a second and the whole preparation takes less than a minute

- Economical

- Safe for the operator

- Corrosion free

- No need for special moulds

- Easy. Automated 1 second process

PinBrazing Cathodic Protection

Safetrack® patented Pin Brazing system quickly create safe, electrical cable connections to steel structures without melting the steel base material as welding methods do. The secret behind the patented system is a specially developed silver-based alloy that melts (650ºC) through a strictly controlled energy distribution from powerful batteries through our self-developed, patented and automated Brazing Gun. Safetrack® PinBrazing is used in many industries to connect cables and is particularly suitable for use in the cathodic protection industry for connecting cables to pipelines, ships, rebar, etc.

- Fast - The PinBrazing process only takes one second and the whole procedure is completed in minutes

- Low temperature - Does not affect internal coatings

- Safe for the material - Does not melt the work surface as exothermic welding does. Only a thin layer of silver is applied between the pipe and the cable wires

- Safe in all weathers

- Suitable for use on pipe-laying barges - No need for special molds

- Safe for the operator - Battery-powered 36VDC system without hazardous materials

- Strong molecular bonding - Silver ensures strong molecular bonding with the lowest possible transition resistance

- Easy-to-use, automated process - Just press the trigger and the automatic 1-second process does the job.

SafeBond® Railway

Attach cables anywhere on the rail, even on the base of the hardest Premium Rails. SafeBond® does not melt down the steel on the railway as for example thermite welding does. Since the use of harder and harder rail is increasing, the SafeBond® silver brazing method has been developed to meet the need for a safe and fast method to apply electrical connections to the rails and create a Safe Bond. Due to the fact that hardening effects are created when the temperature of the rail exceed 720°C/1328°F, the method is based on a special silver alloy (with a lower melting temperature), which is placed beneath the copper cable lug and melted by an electronically controlled energy amount powered by a 36 V DC battery unit.

- Low temperature. Even lower than the PinBrazing method and MUCH lower temperature compared to thermite welding.

- Non-Rail melting© Feature. SafeBond® does not melt down the steel on the railways as for example thermite welding does.

- No metallurgical impact on parent material. Safe for any steel structure.

- Fast Method. A SafeBond® brazing takes only a few seconds.

- Battery powered.

- Lightweight unit. Less than 10 kg. (Econect©)

- Safe for the operator.

SafeBond® Cathodic Protection

SafeBond® - The unique electrical cable bonding system that meets the highest metallurgical requirements for pipelines. The patented SafeBond® system that is developed by Safetrack has already proved its superiority during more than a decade being the only cable application method in the world to be used on the hardest premium rails used in the railway industry. Now we launch this system also to the Cathodic Protection industry where the demands gets higher and higher because of increased use of new materials and where the owner of the pipeline infrastructure wants to protect its property as much as possible.

- Low temperature. Even lower than the PinBrazing method and MUCH lower temperature compared to thermite welding

- Non-Pipe-melting© properties. SafeBond® does not melt down the steel in the Pipeline as for example thermite welding does

- No metallurgical impact on parent material. Safe for any steel structure

- Fast Method. A SafeBond® brazing takes only a few seconds

- Battery powered

- Lightweight unit. Less than 10 kg (Econect©)

- Safe for the operator

SafePlug® Rail web connection

Safetrack® patented SafePlug® is the new generation of rail web connections with

optimal performance. SafePlug® is developed to obtain as low transition resistance as possible between the cable lug and rail. The patented contact cone allows a much greater contact pressure and maintains the pressure to withstand vibrations in the rail even in large temperature changes. The electrical interfaces and contact surface also become much larger thanks to this design.

- Patented extra copper cone ensure constant contact pressure between rail and bushing!

- Double contact surfaces.

- Simple to install - No special training needed.

- Can be installed in any kind of weather.

- For multiple cables and maximum flexible solution, see SafePlug® Combi.

- No hydraulic tool needed to expand bushing - Use Impact Wrench or torque wrench.

- Tested with 35 000A (M12), 25 000A (M10).

SafeGrip™ Rail Contact Bond

SafeGrip™ is used as a stationary or temporary connection of cables to the rail.

It can also be used as a temporary connection between rails while rails are being changed. One size fits several different rail profiles. SafeGrip™ does not need to be adjusted or tightened after a period. The special Swedish spring steel makes sure that the screw always keeps a tight pressure against the rail.

- Over 50 years excellent experience

- Special spring steel of clamp ensure excellent contact

- Vibration-proof

- No cleaning of the rail

- Optional lockable

- Excellent performance in cold climates

- Easily fitted with just a spanner

- Large contact surface on contact screw

- No maintenance required! No filing of the contact surfaces as others etc.

- Can be reused year after year

- One size fits several rail profiles

BUSINESS HOURS

Mon - Fri

07:30 - 16:00

Safely connecting the world!

our locations